Force Sensors

Embedded Force Sensors

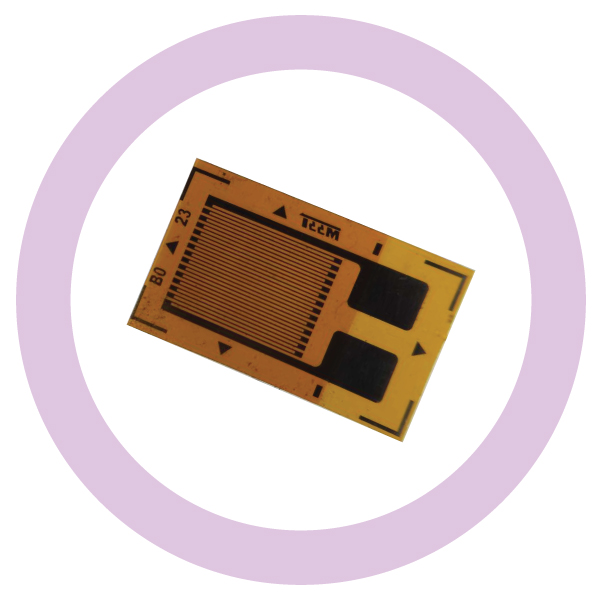

FlexiForce force sensors are ultra-thin and flexible printed circuits, which can be easily integrated into force measurement applications. FlexiForce sensors are available off-the-shelf, or can be customized for unique product designs..

FlexiForce™ embedded sensors measure force between almost any two surfaces and are durable enough to stand up to most environments. FlexiForce sensors are ideal for integrating into OEM products because their thin, flexible profile allows them to measure forces where larger, bulkier technologies can not.

FlexiForce sensors can also be customized to meet the specific needs of your product design and application requirements.

There are 4 key uses for FlexiForce sensors. They detect and measure*:

FlexiForce sensors can also be customized to meet the specific needs of your product design and application requirements.

There are 4 key uses for FlexiForce sensors. They detect and measure*:

- Force from an applied load

- Rate of change of a force load over time

- Force thresholds to trigger appropriate action

- Contact and/or touch

Why OEMs Choose FlexiForce Sensors to Embed in Consumer Products

- Unique form factor – sensors can be custom designed in a variety of shapes and sizes to meet your application and product needs

- Operational capabilities – we offer three pressure-sensitive variations to meet your application and product needs: standard, enhanced, and high temperature.

- Cost Effective – our embedded sensor solutions provide you with a wide range of value-added products, services, and resources to help make the entire design-in process efficient and economical.

- Application Engineering/Integration support – our dedicated application engineering team is here to ensure a successful product integration. They have compiled some sensor integration resources to get you started.

An Overview of FlexiForce Sensor Technology

Easily Embed Sensors in Your Product

Our thin, customizable FlexiForce™ sensors are a cost effective force measurement solution for consumer products. With our engineering expertise, these sensors can easily be designed into products across various markets. These customizable sensors can be produced in high quantities with a quick design time. The sensors are ideal for consumer products due to their ability to withstand various storage temperatures and conditions.FlexiForce™ Custom Force Sensors

Choosing FlexiForce for your embedded force sensor application carries a variety of advantages over the competition, including:- Superior linearity & accuracy (±3%)

- Expert technical guidance in custom solutions

- Wider range of forces

- Sensor output is not a function of loading area

- High temperature versions (up to 400°F) available

- Custom sensors are 100% tested to ensure they meet agreed-upon specifications

- We accept custom jobs with quantities as low as 1000 to as high as millions of sensors

Our Expertise

Our experienced engineering team works closely with you throughout each stage of the design process to ensure the best sensor design for your application. For customers who need custom application software to complement their sensors, we team up with trusted partners to combine our expertise and develop complete specialized solutions.In addition to our embedded force sensors, we have a complete product line of sensors for embedded systems that include matrix pressure mapping sensors and product design solutions.

Sensor Quality, Accuracy, and Application Engineering Expertise Sets FlexiForce Apart

I was looking for a thin, flexible film to measure force in my device; something that would not interfere with its size. We looked at some competing thin film force sensors but your FlexiForce product was more accurate in terms of feedback and linearity. The technical expertise and product quality were also important for us since we needed to get through the FDA approval process. I would recommend FlexiForce sensors to any design engineer who is looking to measure force feedback without compromising the size or weight of the deviceHank Daniecki, RGD Technologies

How Force Sensor Technologies Compare

Load Cells

- Accurately measures force load on a single sensing point

- Tend to be bulky and heavy, thus making them difficult to embed into compact spaces or designs

- Require significantly more power than other sensor technologies

- Require routine factory re-calibration

FlexiForce Sensors

- Printed force-sensitive resitors that are used to measure compressive loads

- Ultra-thin, flexible form factor allows them to be embedded into small, compact spaces

- Low power requirements

- Able to function on simple circuitry

Strain Gauge

- Highly accurate, and small in size

- Require complex circuitry, often requiring 3rd-party outsourcing

- Can be expensive to integrate

Advantages of FlexiForce Sensor Technology in Embedded Applications

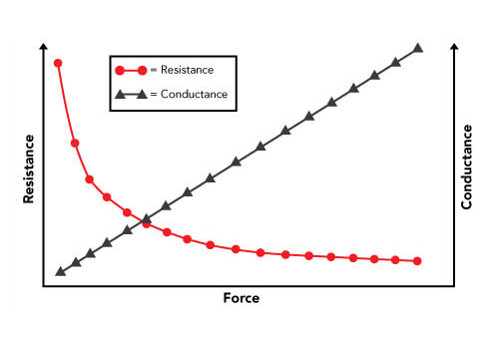

The FlexiForce sensor acts as a force sensing resistor in an electrical circuit.

When the force sensor is unloaded, its resistance is very high. When a force is applied to the sensor, there is a proportional decrease in resistance.

The conductance (1/Resistance) exhibits a linear response, as illustrated above.

When the force sensor is unloaded, its resistance is very high. When a force is applied to the sensor, there is a proportional decrease in resistance.

The conductance (1/Resistance) exhibits a linear response, as illustrated above.

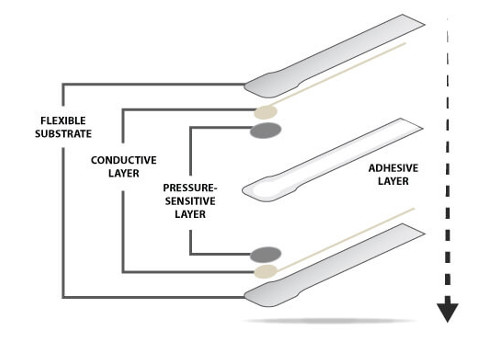

The unique construction of FlexiForce sensors brings the following advantages to your product design:

- thinness [0.008 in. (.203 mm)]

- better linearity than other force sensitive resistors, which simplifies calibration

- measurement of higher loads than other force sensitive resistors

- stable output with respect to load area