Gasket Research and Design

Measure the dynamic pressures that occur in an around various parts of an engine gasket for improved design.

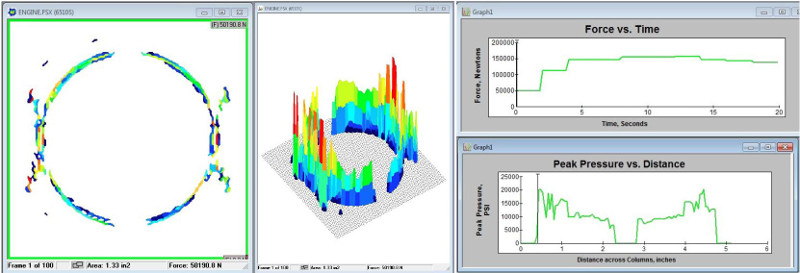

Evaluate Engine Gaskets With Pressure Distribution

Challenge

An important factor in maximizing the efficiency of an engine is making sure the combustion opening is properly sealed through the entire combustion cycle. Decisions need to be made about the block and head structure, fasteners, lubricants, torque, torque sequence, and gasket design.Solution

I-Scan™ pressure mapping sensors can be inserted into and around the various engine gaskets, seals, and fasteners to measure the dynamic pressure distribution at these locations. The system provides valuable pressure measurement data to assist designers and FEA modelers who make decisions about these components. I-Scan can also be used for tests such as validating engine assembly techniques and “motoring” the engine to characterize the seal pressure changes that occur due to vibration, cylinder pressurization and torque.Tekscan’s patented, thin-film sensors are available in different pressure ranges, are reusable, and provide accurate pressure readings. With the help of our highly qualified sales and engineering support team, each system is configured to meet your specific needs.

Gasket Seal Pressure Measurement Applications

- Identify uneven pressures and poor quality seals

- Before and after adjustment comparison

- Reliability testing

- Design verification testing

Benefits of Pressure Mapping

- Provides data for improved design

- Minimize product waste

- Increase manufacturing yields

See how Pressure Mapping Technology can help automobile manufacturers obtain dynamic pressure data to extend the life of vehicle components, like engine gaskets: