Nip Measurement

Nip Measurement

Ensuring uniform nip pressure across the entire surface area of those rolls is crucial to producing a reliably consistent product, maintaining productivity, minimizing machine down time, reducing waste, and more.Obtain a uniform nip impression for roll setup, maintenance, consistency, and longevity

Taking routine nip impressions can help identify:

- Nip pressure and uniformity

- Roller alignment

- Proper machine setup

- Crowning (under- or over-crowning)

- Diameter variations

- Deflections

- Blanket & surface wear

Nip Pressure Measurement Option

There is no “one-product-fits-all” approach but depending on your application needs Tekscan offers three solutions:Fujifilm Prescale Film

single-use nip impression paper

Primary Use: Maintenance Tool

Also known as nip impression paper or a Fuji impression, Prescale film is used to measure pressure between nip rolls and calender rolls.

- Snapshot pressure measurements

- Visual pattern of peak pressure

- One-time use

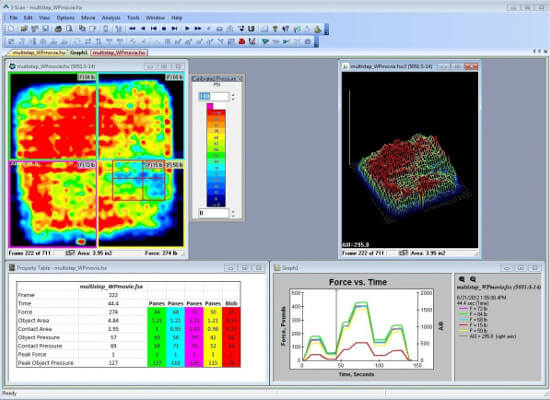

I-Scan

multi-use nip pressure measurement system

Primary Use: Instrumentation Setup

A powerful, versatile tool that accurately measures and analyzes dynamic contact pressure between rolls.

- Used to understand full surface area of the nip

- Over 200 sensors to choose from in different shapes and pressure ranges

- Real-time display of pressure sensor data

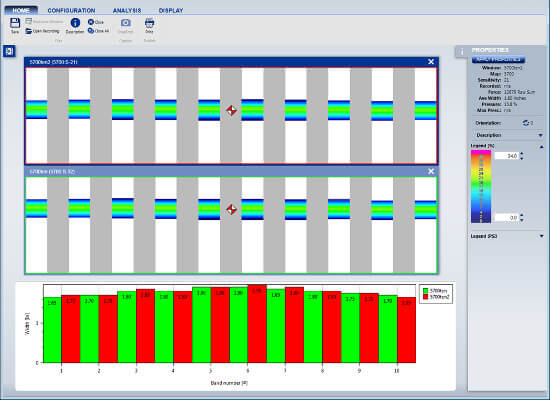

NPAT

advanced nip pressure alignment tool

Primary Use: Maintenance & Setup Tool

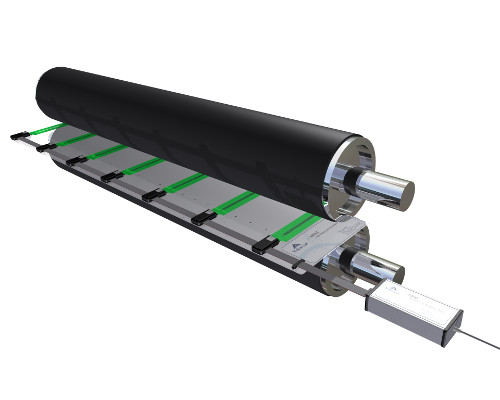

The NPAT™ captures nip footprints and relative pressure distribution between nip rolls.

- Used to measure pressure distribtion, nip width, and cross width across rolls

- Clear visual representation of rolls using static snapshots

- Ideal for large nip roller areas

Comparison of Nip Impression Systems

FujiFilm Prescale (“Nip Impression Paper” / “Fuji Impression”)

Nip impression paper is used to measure contact pressures and is as easy as passing the film through the nip rollers. The film structure consists of micro-encapsulated color forming and developing material. When pressure is applied to the film, a red color impression is formed in varying density according to the amount of pressure and pressure distribution.

I-Scan™

I-Scan is a versatile solution for optimizing a process or manufacturing parameters. The I-Scan nip impression sensor is placed in the nip for real-time roller pressure measurement. With a wide range of sensor form factors and data analysis tools in the software, I-Scan is a powerful tool for a research and development team to improve yield.

I-Scan is a versatile solution for optimizing a process or manufacturing parameters. The I-Scan nip impression sensor is placed in the nip for real-time roller pressure measurement. With a wide range of sensor form factors and data analysis tools in the software, I-Scan is a powerful tool for a research and development team to improve yield.

Nip Pressure Alignment Tool™ (NPAT)

NPAT is an advanced, easy-to-use tool used to capture nip footprints and relative pressure distribution between nip rollers. The system utilizes a sensor made up of an array of thin and flexible pressure sensitive bands, which can be configured to match the size of an application.

NPAT is an advanced, easy-to-use tool used to capture nip footprints and relative pressure distribution between nip rollers. The system utilizes a sensor made up of an array of thin and flexible pressure sensitive bands, which can be configured to match the size of an application.

Compare Solutions with this Chart

| Nip Impression Paper | I-Scan | NPAT | |

|---|---|---|---|

| Primary Use | Maintenance tool | Instrumentation setup. Used by R&D engineers to optimize processes. | Maintenance & setup tool |

| Data Captured | Static display of pressure that captures peak load only; No timing data | Real-time, dynamic display of contact area of the nip | Relative nip uniformity and pressure distribution |

| Ideal Nip Roll Size | Cut to size | > 450 mm (18 in) | 450 mm (18 in) to 10,973 mm (432 in) |

| Analysis Capabilities | Digital scanner; software only displays degree of pressure | Featured packed, robust software with in-depth analysis tools and features | Robust software with analysis tools and features |

| Efficiency & Productivity | Single-use product with a cumbersome setup process | Reusable, mix and match sensors capturing in-depth analysis of nip contact area | Reusable sensors that capture changes in pressure distribution in real-time |