Pressure Mapping Technology

Pressure Mapping Technology

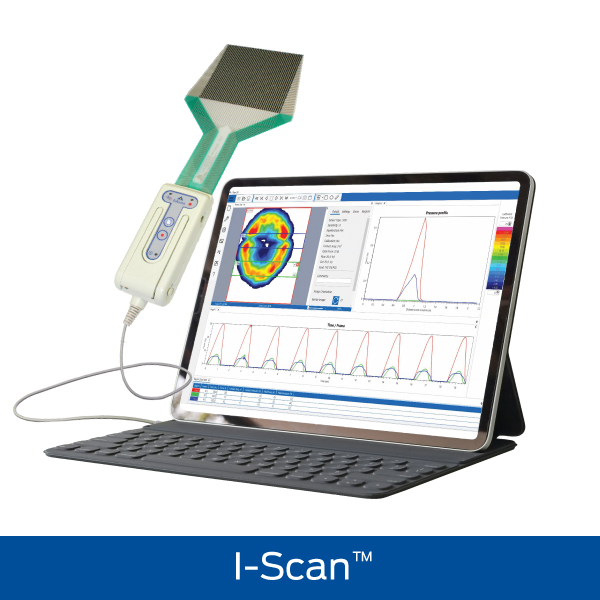

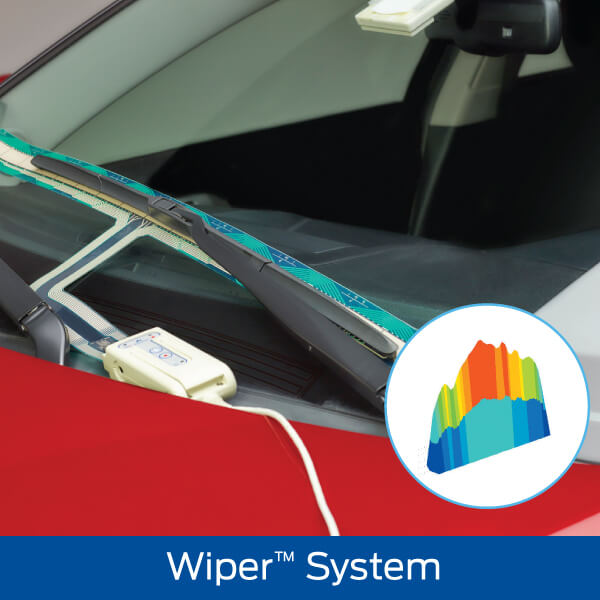

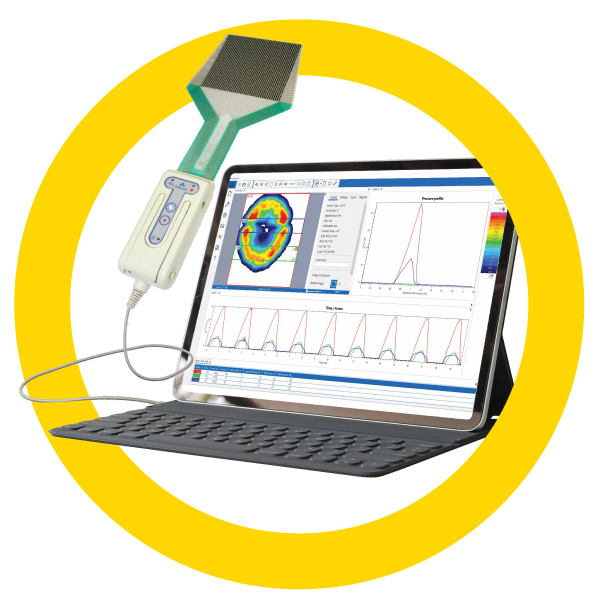

Measure interface pressure between two surfaces, utilizing a thin and flexible sensor. The resulting data and our analysis tools offer insights to enhance product design, manufacturing, quality, and research.What is a Pressure Mapping System?

Pressure mapping is a unique test & measurement technology and prime example of a wide-reaching R&D tool. Top tier companies have successfully used our systems to help solve application challenges, improve product design, and more.- Analysis tool that maps interface pressure and provides insight for a better understanding of surface behavior

- Provides key metrics including total force, peak pressures, and center of force

- Clear visual representation of pressure distribution

- Multiple graph options to plot data

- Access real time or recorded data

- Components include: sensors, data acquisition electronics, and software

- Over 200 standard sensors with different shapes, sizes, resolution, and pressure ranges; custom sensors available

- High speed and wireless capabilities

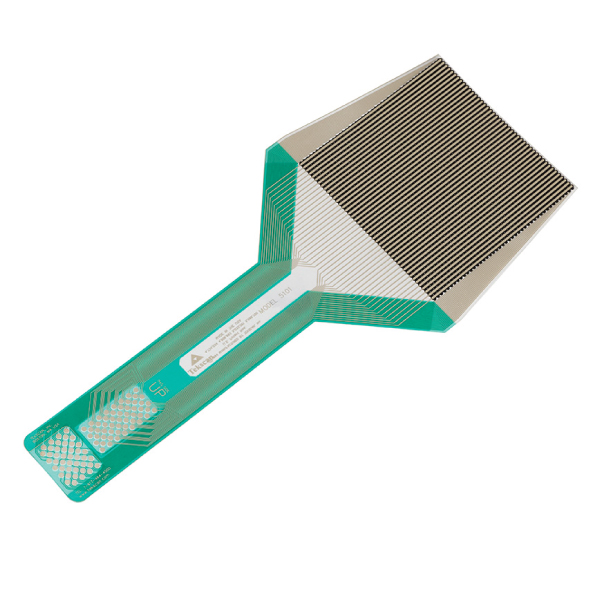

Sensors

- Minimally invasive high resolution sensor that is thin and flexible

- Over 200 standard sensors with different shapes, sizes, resolutions and pressure ranges

- Customizable to unique form factors and pressure ranges to meet specific applications

Electronics

- Scan thousands of sensing points within each sensor

- Data is instantly relayed to the software on your PC via a USB cable

- High speed and wireless options available

Software

- Software displays the pressure distribution data, in multiple formats, for superior analysis

- Real-time display of pressure sensor data in 2D & 3D

- Display peak pressures and center of force

Pressure Mapping – A Design Engineer’s Magnifying Glass

Watch this five-part video series covering Pressure Mapping Technology’s several uses to help enhance R&D processes:

Common uses for Pressure Mapping in R&D

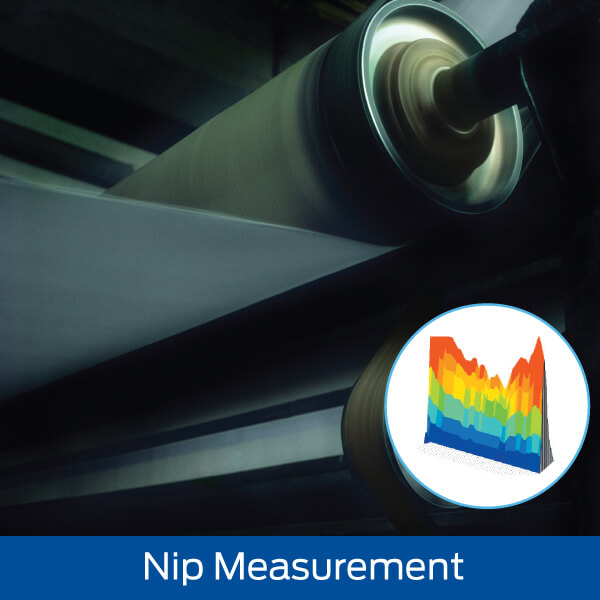

- Evaluating component press fits and seals

- Evaluating product performance

- Machine design and setup precision

- Comfort and ergonomic assessment

- High-speed impact testing

How Pressure Mapping Compares to Other Technologies

Load Cells

- Accurately measures force load on a single sensing point

- Multiple load cells are required to measure a pressure array

- Tend to be bulky, thus making them difficult to position in a manner desired for collecting relevant data

Pressure Mapping Technology

- Sensors are minimally-invasive, making it a viable testing solution for examining pressure between nearly any two mating surfaces

- Captures the entire range of pressure occurring over the entire test

- Software recording & analysis features allow the user to analyze real-time data, an export into user-friendly file formats

- Systems can be calibrated to a known force for more precise data collection

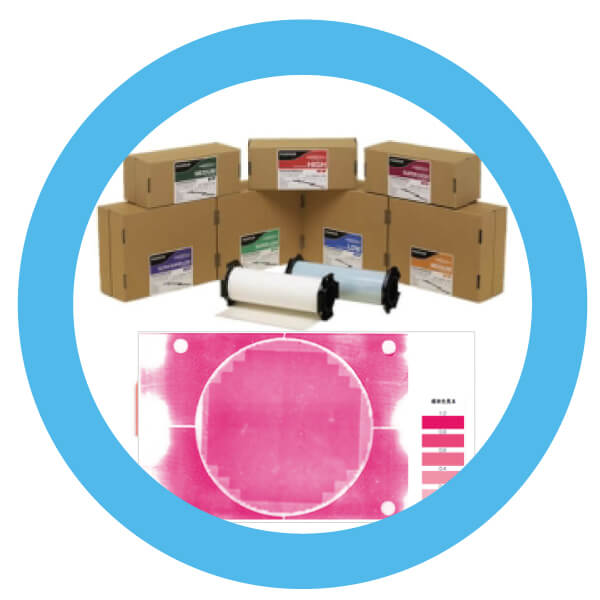

Pressure Indicating Film

-

An affordable single-use method to capture the moment of peak pressure during a testing process

- However, it does not provide evidence of when that peak moment occurred in the testing process

- Only displays a degree of pressure in a single test (cannot be calibrated)